Rolling Stock Project

Siemens Nexas Midlife Works Project

Project Overview

Project Client: Metro Trains Melbourne (MTM)

Year of Completion: 2025

The Siemens Nexas Midlife Works Project was a comprehensive interior and exterior overhaul aimed at improving accessibility and overall passenger experience. This initiative was developed in consultation with MTM, key stakeholders, and human factors specialists to ensure that the enhancements met regulatory and user needs.

SCG played a pivotal role in the concept development, design, prototyping, validation, and implementation of the upgrades, ensuring seamless integration within the fleet.

Project objective :

The primary goal of this project was to improve accessibility and passenger comfort within the Siemens Nexas fleet while ensuring compliance with relevant safety and accessibility standards.

Scope of Work :

◘ Interior and Accessibility Upgrades:

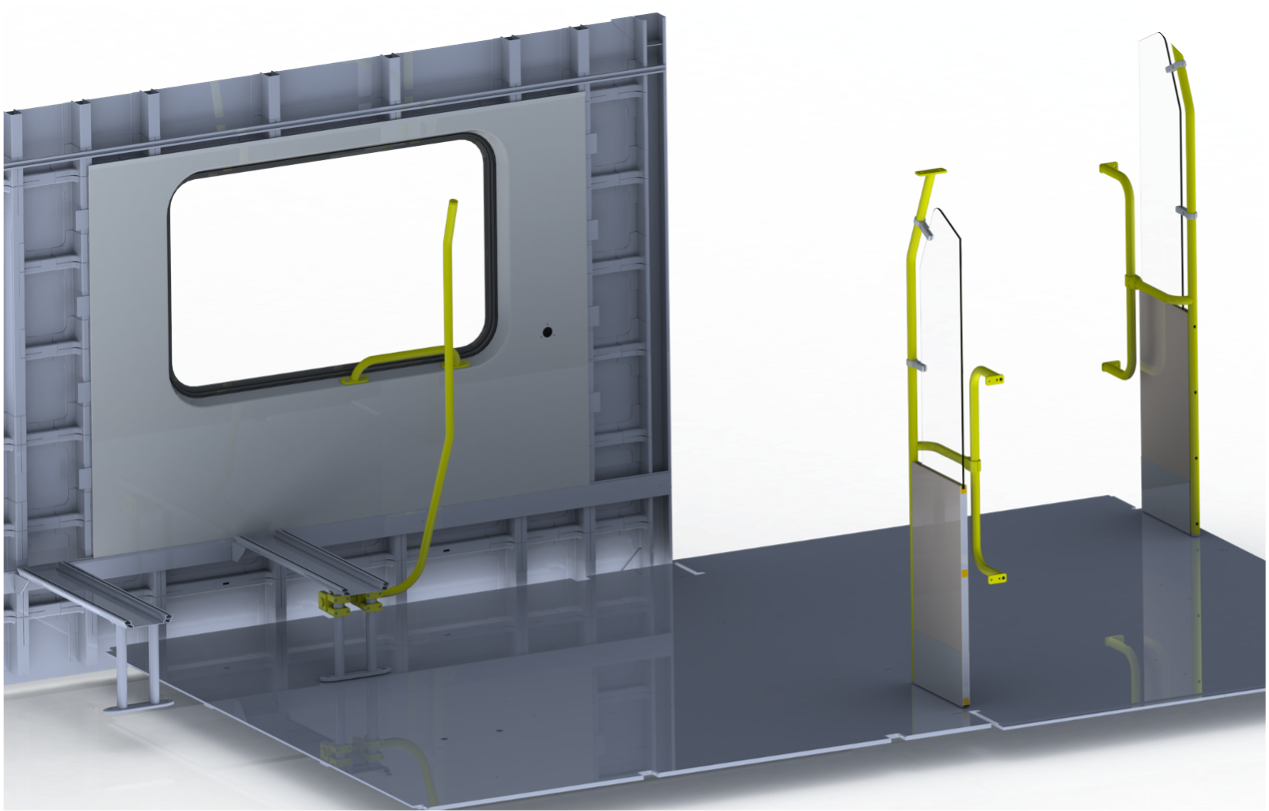

• Installation of new grabrails in accessibility spaces

• Installation of new ‘Disability Discrimination Act’ buttons in all accessibility spaces

• Relocation of select passenger emergency intercoms

• Improved ingress and egress for accessibility spaces

• Complete overhaul of interior decals

• Replacement of seat fabric and foam

• Conditional repair of seat frames

◘ Exterior Enhancements:

• Complete replacement of external decals and livery

◘ Mechanical and Structural Upgrades:

• Bogie fatigue assessment

• FEA validation of new handrail designs

• Reverse engineering and 3D modelling of train structures

• Manufacturing drawings issued for compliance and configuration management

Project delivery :

◘ Project Management:

• Scope and budget development

• Development of requirements matrix

• Procurement and tendering processes

• Risk assessment and mitigation (ISEA, SOP, SWMS)

• Customer communication and stakeholder engagement

• Identification and engagement of specialists (human factors, bogie design experts)

• Organisation and execution of design mock-ups for user evaluation

◘ Mechanical Design Engineering:

• Standards identification (DSAPT, accessibility, structural)

• Development of requirements matrix

• Management of Change (MOC) and Engineering Change documentation

• Concept development and prototyping

• Reverse engineering and modelling of train hardpoints

• Manufacturing oversight, including onsite auditing, first article inspections, and inspection/test plan documentation

Key innovations :

◘ User-Centric Design: Engaged human factors specialists and disability users to evaluate and refine accessibility improvements.

◘ Enhanced Passenger Experience: Upgraded seating, improved accessibility features, and modernised decals to create a more inclusive and comfortable environment.

◘ Advanced Engineering and Testing: Utilised FEA to validate new handrail designs and performed crib testing for seat materials to ensure durability and compliance.

◘ Sealmess Execution: Delivered a high-quality, fully integrated solution within the operational constraints of a live rail environment.

SCG’s successful execution of the Siemens Nexas Midlife Works Project underscores our commitment to delivering high-quality, user-focused rail solutions. By leveraging our expertise in project management and mechanical design engineering, we have enhanced the safety, accessibility, and aesthetic appeal of the Siemens Nexas fleet, ensuring a better experience for all passengers.